NEWS

Review of NQ Academy Webinar #7: Geothermal Production Processes through Geochemical Interventions

NQ News

Thursday, April 1, 2021

NQ Academy Webinar #7 has been held on March 27, 2021. The webinar entitled “Optimization of Geothermal Production Processes through Geochemical Interventions for Sustainable Geothermal Development” was presented by Muhamad Andhika, M.Si. He is a Production Geochemist at Sarulla Operation Ltd and has professional experiences in exploration and production geochemistry for more than 15 years. The 7th NQ Academy Webinar was well organized and attended by more than 100 participants. Dr. Yunus Daud, Founder of NewQuest Geotechnology was the host in the Webinar.

At the opening, the host explained that geothermal is a heritage that can be passed on to our future generations. By conducting monitoring using geochemistry, it can overcome several problems in geothermal production such as scaling and corrosion related to the exploitation of geothermal fluids. The challenge in this stage is how to optimize the production as well as solving the production problems in the same time.

So far, 84% of geothermal fields that have been operated in Indonesia is liquid dominated system (LDS), while 16% of the existing geothermal fields is vapor dominated systems. Due to Volcanic fingerprint, brine in geothermal fluid is not only in near neutral condition but also having acid pH. Near neutral pH will have scale problem and acidic pH will tends to bring corrosion in the production facilities.

In a liquid dominated system, there are several powerplant generators that can be used such as direct use, single flash, double flash, binary brine, and integrated combine cycle. All of them almost have the same problem, namely silica scaling.

Solubility of Silica is very dependent on concentration and temperature (prograde solubility). The most intriguing fact from silica scale is that the form of it is not instantaneously and requiring an induction period. This transition phase is often used to inhibit silica deposition using the pH modification method.

In LDS, they will have either near neutral production wells, acidic production wells or both at the same time. Commonly, the geothermal companies will only use near neutral wells as production wells since it is easier to handle due to a lower corrosion risk. It will require higher costs if we develop an acid well, because it needs a better well casing and the geothermal fluid must be neutralized before entering the powerplant. So far only PGE (Lahendong) and SOL (NIL) operate their acid wells.

Scaling problem does not only occurred at the plant but also in the wellbore. This problem reduces WHP and mass flow, and also causes higher steam phase changes as well as increasingly concentrated brine which causes scaling in the wellbore. Usually, the pH becomes higher in the neutral wells.

In Vapour Dominated systems (VDS) there is also major problem with the calcite scale caused by a decrease in WHP, changes in pH, and loss of CO2. Solubility of calcite is determined by the solubility of carbonate species. CO2 plays a big role in calcite solubility since it affect carbonate species. When CO2 experience degassing, the calcite saturation index increase 100 to 1000 times stronger rather than the effect of Ca concentration.

The important thing that needs to be done is geochemistry monitoring, how to identify problems that exist both in the upstream and downstream areas. It needs to be budgeted to build and buy laboratory equipment to support monitoring programs. The programs will allow us to know the condition of calcite and silica oncentrations, and even knowing the possibility of corrosion. The sampling fluid must be conducted properly to determine the fluid quality and purity.

Apart from the general problem of silica scale, there is also potential for sulfide and sulfur scale. Sulfide is the largest content after CO2 which dissolves in base pH. It must also be considered the pH, TDS, and purity of the sulfide. This can be prevented with a steam wash or turbine wash which must be done with fluids with very low oxygen and low TDS to prevent corrosion.

The most important thing in handling the silica scaling is to know the stages of the scaling process conditions, whether it is in the monomeric, polymeric, or deposition form. In monomeric conditions, it will be easier to avoid silica deposition or silica polymerization by using acid (ph modification) or using an inhibitor.

But, silica scaling in the polymeric condition will be more difficult to overcome. The way that can dissolve the silica scaling is using caustic injection. Or we can also use chemical inhibitors using polymers that are not harmful to the environment and do not change the pH. When the silica deposition happened, we can just remove it using mechanical cleaning which requires a shutdown of the plant.

In acid wells, the caustic injection can also be done, but it should not be excessive, which causes the pH to be higher, resulting in scaling. We can also combine it using corrosion inhibitors.

In the end of the presentation, the speaker give a short summary. The most common problem in geothermal production is scale and corrosion. Different plant process types will have different critical locations and require unique solutions. Liquid dominated system mostly encounter silica deposition and metal silicate in the pipeline. Vapor Dominated system usually having calcite deposition in the wellbore or in the turbine. The turbine also happened some scaling problems such as Silica and sulfide or sulfate scale. But overall, it could be solved properly by geochemical interventions supported by well managed monitoring programs.

Gravity Survey and Magnetotelluric Data Processing of Jailolo Geothermal Prospect Area, West Halmahera

NQ News, Monday, 11 April 2022

Press Release: NewQuest Geotechnology Anniversary Day - A Ten Years of Contributions

NQ News, Monday, 25 of October 2021

SPECIAL NQ 10 YEARS ANNIVERSARY DAY “Geothermal Technology Innovations: A Perspective from...

NQ News, Thursday, 21st of October 2021

Special NQ Training: “Magnetotelluric (MT) for Geothermal Exploration”

NQ News, Monday, 4 October 2021

Special NQ Training For Public Society: “Geothermal Energy: A Special Gift for Indonesia”

NQ News, Thursday, 30 September 2021

Review of Special NQ Academy Webinar #10: Technology & Innovation to Accomplish Geothermal...

NQ News, Thursday, 16 September 2021

NQ Ten Years Anniversary: Contributions for National Prosperity Through Continuous Innovations

NQ News, Tuesday, 1 September 2021

NQ Academy Webinar #10: Technology & Innovation to Accomplish Geothermal as Affordable Energy

NQ News, Tuesday, 1 September 2021

Review of NQ Academy Webinar #9: Steam Field Management: Problems and Troubleshootings

NQ News, Monday, 16 August 2021

NQ Academy Webinar #9: Steam Field Management: Problems and Troubleshooting

NQ News, Friday, 30 Juli, 2021

GEOTHERMAL MEDIUM TEMPERATURE RESOURCES IN MALAYSIA, THAILAND AND INDONESIA

NQ News, Wednesday, May 5, 2021

Review of NQ Academy Webinar #8: Lessons Learned from Geothermal Exploration in Muara Laboh

NQ News, Monday, May 3, 2021

NQ and IMT-GT Webinar on Exploration & Utilisation of Low-Medium Geothermal Resources...

NQ News, Friday, April 23, 2021

NQ Academy Webinar #8: Lessons Learned from Geothermal Exploration in Muara Laboh

NQ News, Wednesday, April 21, 2021

NQ Academy Webinar #7: Optimization of Geothermal Production Processes through Geochemical Interventions for ...

NQ News, Thursday, March 25, 2021

Review of NQ Academy Webinar #6: From Large-Scale Tectonics to Field-Scale Geothermal Systems

NQ News, Wednesday, March 3, 2021

NQ Academy Webinar #6: From Large-Scale Tectonics to Field-Scale Geothermal System: Lessons Learned from Sumatra

Thursday, February 25, 2021

Review of NQ Academy Webinar #5: Final Preparation of Government Drilling Program

NQ News, Friday, February 5, 2021

WKP Cisolok Cisukarame: First WKP to drill in Government Drilling Program

NQ News, Tuesday, February 2, 2021

Review of NQ Academy Webinar #4: Geochemical Signatures over Volcanic Geothermal Systems

NQ News, Wednesday, December 23, 2020

NQ ACADEMY WEBINAR #4: Geochemical Signatures over Volcanic Geothermal Systems

NQ News, Wednesday, December 16, 2020

The Three Million Dollars Well: A Lesson Learned from Geothermal Drilling in Indonesia

NQ News, Monday December 7, 2020

NewQuest Geotechnology & North Tech Drilling Signed a Strategic Partnership Agreement

Press Release: Monday November 30, 2020

NQ ACADEMY WEBINAR #3: THE THREE MILLION DOLLAR WELL: A LESSON LEARNED FROM ...

NQ News, Thursday November 19, 2020

NQ SURVEY AND EXPLORATION IN MALAYSIA AND PROSPECTS FOR GEOTHERMAL DEVELOPMENT ...

NQ News, Monday November 16, 2020

WKP TANGKUBAN PERAHU, DEVELOPING GEOTHERMAL IN VOLCANO TOURISM LOCATIONS

NQ News, Monday October 26, 2020

"BEST GEOTHERMAL SERVICES COMPANY" AWARD FOR NEWQUEST GEOTECHNOLOGY

NQ News, Wednesday September 30, 2020

WKP ATADEI, A PARTNERSHIP OPPORTUNITIES ON PLN’s GEOTHERMAL WORKING AREA (WKP)

NQ News, Monday September 28, 2020

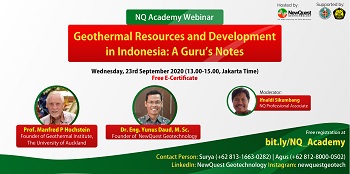

DR. YUNUS DAUD LAUNCH NQ ACADEMY ON THE 1ST NQ ACADEMY WEBINAR EVENT

NQ News, Friday September 25, 2020

NewQuest footprint in Blawan - Ijen WKP, First Discovery of hidden geothermal in Indonesia

NQ News, Friday August 21, 2020

RI "Too Preoccupied" with Fossil Energy, Renewable Energy Should Be Accelerated

Friday, 3 February 2017